Metal fabrication is the backbone of countless industries, from construction and automotive to aerospace and custom/bespoke manufacturing. But what exactly goes into transforming raw metal into functional structures, components, and products? Whether you’re a partner or a client looking to understand fabrication better or a curious newcomer, here I will be breaking down the essentials for you.

The Key Steps in Metal Fabrication

1. Designing & Planning (Click to expand)

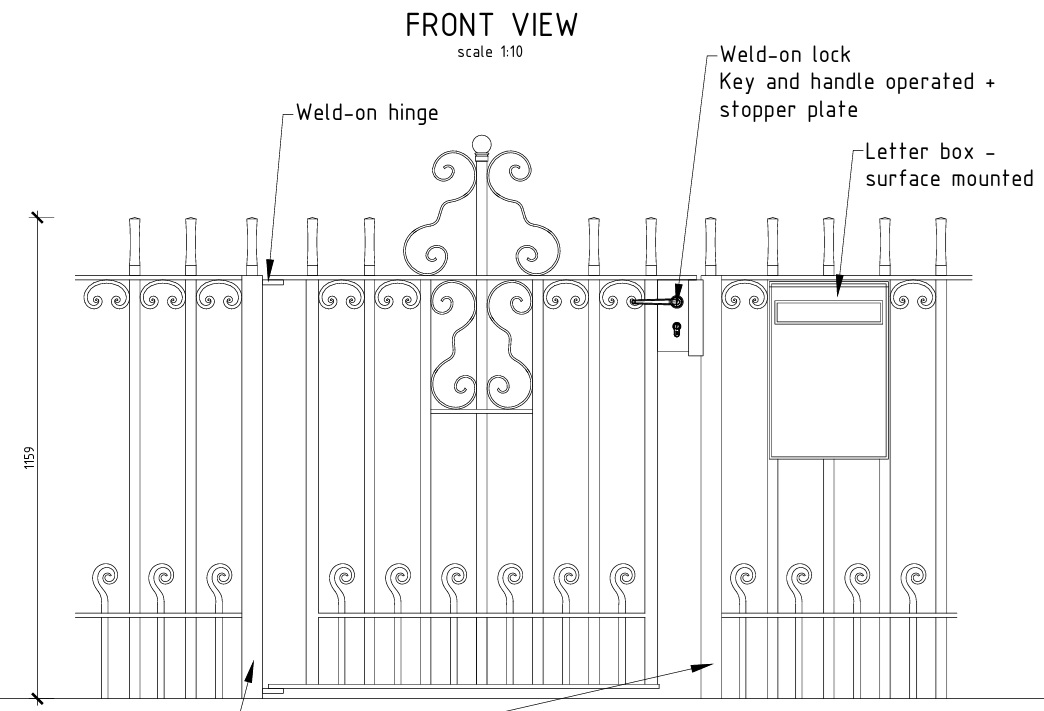

Before the fabrication process begins, designs are created using CAD (Computer aided Design) software to ensure accuracy and efficient. This blueprint guides the fabricator on material selection, measurements, and the best fabrication techniques.

2. Cutting the Metal (Click to expand)

Cutting is one of the first steps in fabrication. Metal sheets, pipes, or bars are cut to the required size using methods such as:

- Laser Cutting: Precise and ideal for detailed designs.

- Plasma Cutting: Efficient for thick materials.

- Sawing: A traditional method for simple cuts

- Water Jet Cutting: Uses high-pressure water to cut without heat damage.

3. Shaping & Forming (Click to expand)

Once cut, metal must be shaped into the desired form. Techniques include:

- Bending: Using press brakes to create curves.

- Rolling: Forming sheets into cylindrical or conical shapes.

- Stamping: Pressing designs into metal.

4. Joining & Assembly (Click to expand)

Fabricators join metal components together using welding, riveting, or fastening techniques. Welding is particularly vital in this industry, with the most common methods being MIG, ARC/MMA and TIG welding (Check out our blog post on TIG welding to better understand this process). Proper joining ensures strength, durability, and structural integrity.

5. Finishing Touches (Click to expand)

After assembly, finishing processes enhance the product’s durability and appearance. These can include:

- Grinding & Polishing: Smooths rough edges and enhances aesthetics.

- Powder Coating, or Painting: Provides protection against corrosion and wear.

- Galvanising: Adds a zinc coating for rust resistance.

Now you know!

Metal fabrication plays a crucial role in industries worldwide. And whatever your needs are, Porfan Metalwork can fulfill your every require whether it’s structural steelwork, or a repair job. Our skilled fabricators ensure that their jobs are solid, functional and built to last.